Streamlined Fabrication Process for Efficient Site Delivery

Our high-tech equipment is performed in the plant at different stages using raw materials.

Our machines are then used to cut and drill, followed by fitting and welding. After the materials

are painted, they are loaded carefully on the truck ready for the site. The raw material is supposed

to come in the factory, be super fast fabricated to erectable field parts, and be delivered.

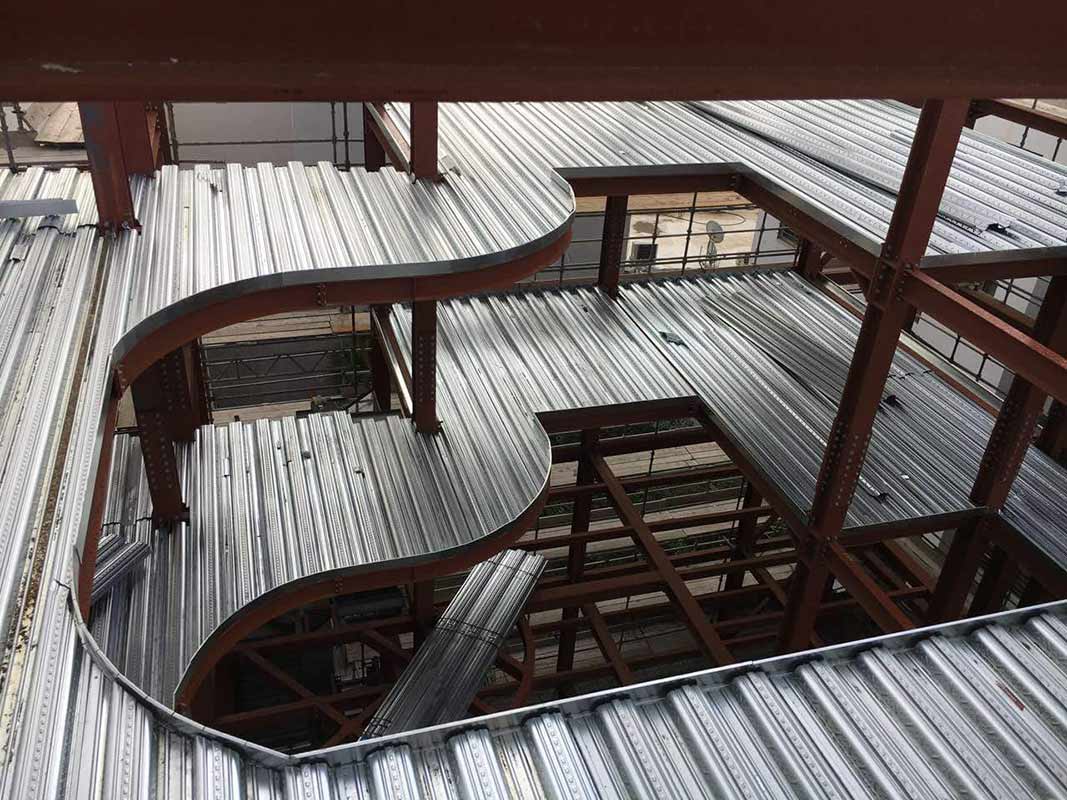

Advanced Machinery and Skilled Workforce for Precise Steel Processing

We employ highly skilled machine workers to operate the series of machinery required to process

the steel profiles. Our computer-supported machinery amongst others include a shot blaster,

cutting/drilling/coping/marking lines, plasma/oxygen flat plate cutting beds, plate drilling machine,

press brake, slitter, section bender, pre-camberer, and an automatic painting and drying machine.

Our personnel includes professional fitters and certified welders. For all projects, non-destructive

tests are performed on regular basis to certify the quality of welds and paint system.